FLEXIBLE FIRE SPRINKLER HOSE | TECHNOFLEX CORPORATION JAPAN

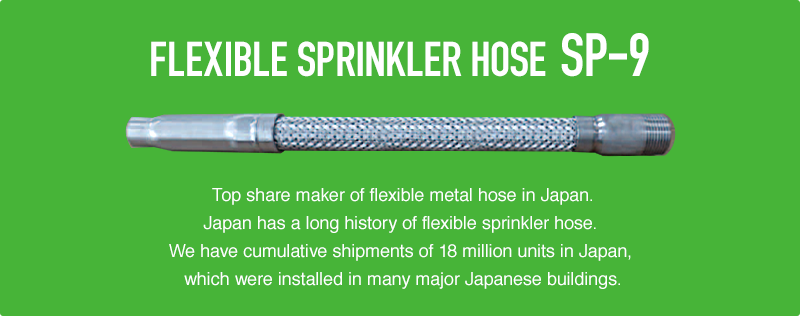

- Japanese excellent quality and high QA capabilities.

(Planned & Designed by Japan HQ, Manufactured at our 100% owned facilities in Japan, China and Vietnum) - First Japanese Manufacturer releasing the flexible sprinkler hose to US Market.

- TECHNOFLEX CORPORATION. Established in 1977.

- We have good sales achievements over 23 years and much experience with installation trouble shooting.

- We always verify product performance under various conditions using mock-up piping in the laboratory.

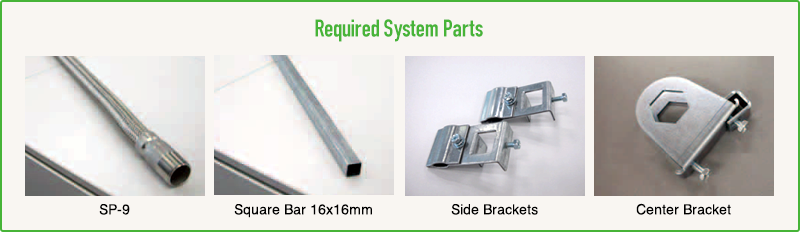

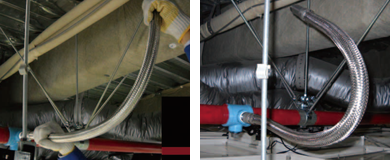

- Braided:flexible and easy installation.

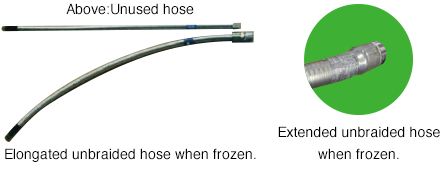

- No elongation of fexible hose due to the working pressure increase caused by ambient temperature change.

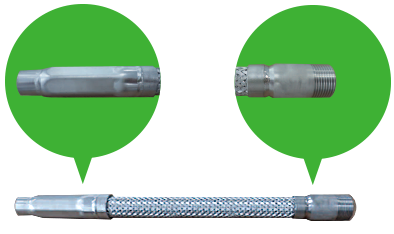

- Parts are all stainless. Welded inlet/outlet type.

- No use of packing or other materials that degrade over time and leak.

- Stress relief by heat treatment.Keep good corrosion resistance as stainless Steel.

- Only two connection points.Reduce the inspection time for leakage.

- Firm fittings which enable to replace SP head

even after installed.

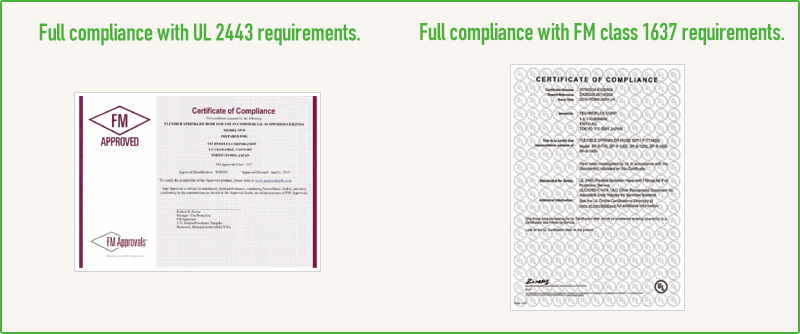

(compliant with UL 2443 performance requirement)

| Part name | material | detail | Dimension |

|---|---|---|---|

| Inlet fitting | 304SS | Male | NPT 1 |

| Outlet fitting | 304SS | Female | NPT 1/2 |

| Corrugated tube | 304SS | Annular | ID:20.6mm t:0.25mm |

| Braid | 304SS | Wire | Φ0.26mm |

| Model | Rated Pressure. (psi) |

Max. Ambient temp. (°F) |

Assembly Length. Ft(mm) |

Max. No.of 0°bends. |

Min. Bend Radius. (in) |

Eqivalent Length. *C=120(ft) |

Flexibility type |

|---|---|---|---|---|---|---|---|

| SP-9-700 | 175 | 300 | 2.3(700) | 2 | 3.5 | 25 | Limited |

| SP-9-1000 | 175 | 300 | 3.3(1000) | 3 | 3.5 | 41 | Limited |

| SP-9-1200 | 175 | 300 | 4.0(1200) | 4 | 3.5 | 57 | Limited |

| SP-9-1500 | 175 | 300 | 5.0(1500) | 4 | 3.5 | 61 | Limited |

| SP-9-1800 | 175 | 300; | 6.0(1800) | 4 | 3.5 | 70 | Limited |

| Model | Rated Pressure. (psi) |

Max. Ambient temp. (°F) |

Assembly Length. Ft(mm) |

Max. No.of 0°bends. |

Min. Bend Radius. (in) |

Eqivalent Length. *C=120(ft) |

|---|---|---|---|---|---|---|

| SP-9-700 | 175 | 300 | 2.3(700) | 2 | 10 | 37.1 |

| SP-9-1000 | 175 | 300 | 3.3(1000) | 3 | 10 | 59.5 |

| SP-9-1200 | 175 | 300 | 4.0(1200) | 4 | 10 | 74.5 |

| SP-9-1500 | 175 | 300 | 5.0(1500) | 4 | 10 | 80.0 |

| SP-9-1800 | 175 | 300; | 6.0(1800) | 4 | 10 | 85.6 |

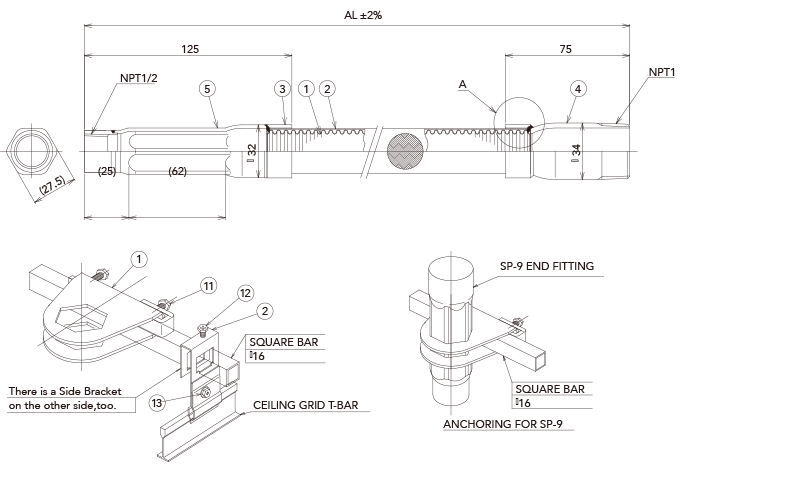

| InletType | Welded straight |

|---|---|

| Outlet Type | Welded straight |

| Intended System Type | Wet system |

| Largest Sprinkler K-factor and Orifice Diameter.(1/2 in outlet) | K=5.6 |

| Specified Hose internal Diameter.In(mm) | 0.811(20.6) |

| Specified minimum spacing for anchoring components attached to the building components.In(mm) |

23.6(600) |

| Specified maximum spacing for anchoring components attached to the building components.In(mm) |

47.2(1200) |

| End use application. | Suspended ceilings |

These flexible sprinkler hose with fittings are intended to use for direct connection to fire sprinklers in accordance with NFPA13

(Standard for the Installation of Sprinkler Systems), 13D (Standard for the Installation of Sprinkler Systems in One- and

Two-Family Dwellings and Manufactured Homes) or 13R (Standard for the Installation of Sprinkler Systems in Low-Rise

Residential Occupancies).

These flexible sprinkler hose with fittings can be installed for use in ceilings with grids that meet ASTM C635 (Standard

Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel

Ceilings) and ASTM C636 (Standard Practice for Installation of Metal Ceiling Suspension Systems for Acoustical Tile and

Lay-in Panels) or meet JIS A 1445 (Testing Methods of Materials for Ceiling Suspension System).

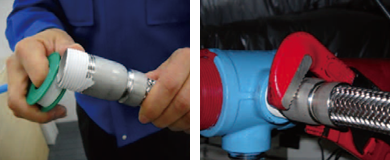

Read and understand all instructions before attempting to install any flexible sprinkler hose fittings. We recommend wearing safety glasses, hardhat and foot protection during installation.

- Apply 3 to 4 wraps of PTFE tape on the inlet Nipple Thread.

- Use Pipe Wrench to connect the inlet Nipple to the branch line. Do not over tighten.

- Make sure both end threads are clean without any damage.

- ・After that, bend up the hose to work easily.

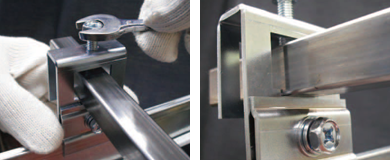

- A side bracket is fixed to a grid T bar.

- Torque is 8.2~8.7N・ m when the side bracket is fixed.

- It connects with the side bracket through a square bar.

- Torque is 5.8~ 6.3N・ m when a the side bracket is fixed.

- Another terminal is fixed similarly.

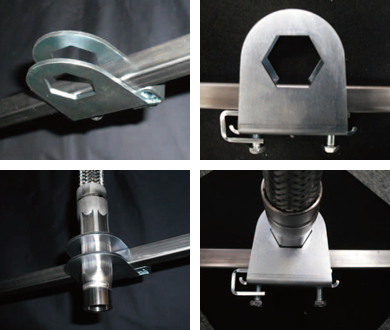

- A center bracket is fixed to the square bar.

- It lets SP-9 flexible hose pass in the hole of the center bracket.

- Caution: The hexagon hole of the center bracket is set in parallel with the square bar(Refer to the fgures). If the hexagon of the hose cannot be set in parallel with the square bar, adjust it by turning it with the inlet Nipple.

- Two bolts of the center bracket is tightened.

- Torque is 5.6~ 6.1N・ m when the center bracket is fixed.

- A sprinkler head is connected to SP-9 flexible hose.

- When the sprinkler head is fixed,torque is considering it as the value specified by the sprinkler head maker.

- Completion of the installation

- SP-9 Sprinkler Flexible Hose must not be installed in a straight position (there needs to be at least 1bend).

- When installed to sprinkler line pipes,do not bend the hose too much. The radius of bending should not be smaller than the “minimum bend radius” .

- SP-9 Sprinkler Flexible Hose and Bracket must not be intermixed with other manufacture’s products.

- Avoid twisting the flexible hose when connecting it to a sprinkler line pipes. The flexible hose cannot absorb twists.